2024-03-08

How to choose the right compression drying system for wind turbine gearbox lubricating oil

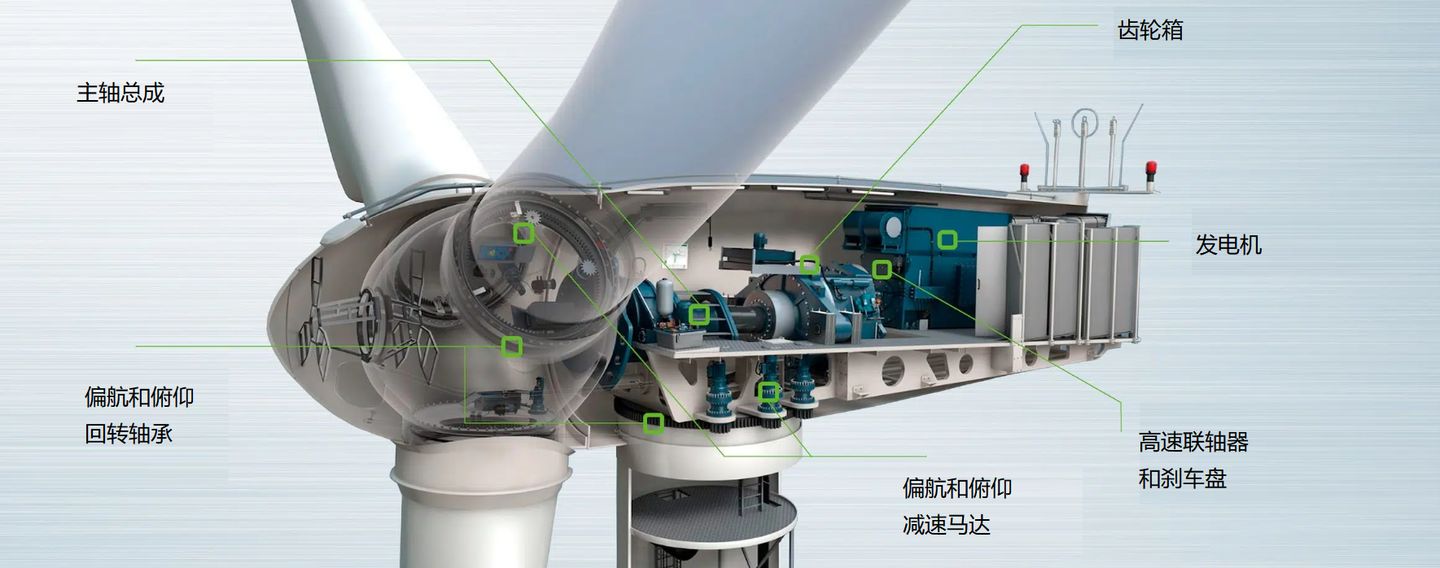

The lubricating oil system of wind turbine gearbox is an indispensable part of wind turbine. Its function is to provide necessary lubrication and cooling for gears, bearings and other running parts. The quality and performance of lubricating oil directly affect the efficiency, life and reliability of the gearbox.

The correct choice of compression drying system is also very important for the quality of lubricating oil. The compression drying system is mainly used to remove moisture and impurities in the lubricating oil, prevent the oxidation and pollution of the lubricating oil, thereby extending the service life of the lubricating oil and protecting the running parts of the gearbox. If the compression drying system is improperly selected or maintained, the moisture and impurities in the lubricating oil cannot be effectively removed, which will affect the normal operation of the gearbox, and even cause the gearbox to malfunction in severe cases, which will affect the stable operation of the wind turbine.

The role of compression drying system

The compression drying system is mainly used to remove the moisture in the lubricating oil, reduce oxidation and pollution, etc. Its function and principle are as follows:

(1) Removal of moisture in lubricating oil: Water is one of the most common pollutants in lubricating oil, and its existence will cause problems such as viscosity change, oxidation acceleration, corrosion and foam of lubricating oil. The compression drying system cools the compressed air below the dew point, condenses the moisture in the air into water droplets, and discharges them through the drainage system, thereby achieving the purpose of removing the moisture in the lubricating oil.

(2) Reduce oxidation: Lubricating oil is prone to oxidation reactions under the action of high temperature, high pressure and oxygen, which leads to deterioration, degradation and failure of lubricating oil. The compression drying system can reduce the oxidation rate of lubricating oil and reduce the degradation and deterioration of lubricating oil by removing oxygen from the air.

(3) Reduce pollution: Lubricating oil will be affected by various pollutants during use, such as dust, metal particles, chemicals, etc. These pollutants can cause problems such as viscosity changes, increased friction coefficient, corrosion and wear of lubricating oil. The compression drying system can remove contaminants from the lubricating oil through equipment such as filters and separators, thereby reducing the impact of pollution on the lubricating oil.

Choosing the Right Compression Drying System

The selection of a compression drying system suitable for the lubricating oil system of a wind turbine gearbox requires consideration of the following factors:

(1) Working environment: The working environment of the compression drying system has an important impact on its performance and life. In the seaside or humid environment, it is necessary to choose a compression drying system with anti-corrosion and anti-rust. In a high temperature environment, it is necessary to select a compression drying system with high temperature resistance.

(2) Gas flow: The gas flow of the compression drying system needs to be selected according to the needs of the lubricating oil system. If the gas flow rate is too small, the drying effect will be poor, and if the gas flow rate is too large, the energy consumption and cost of the equipment will be increased. In general, the gas flow should be slightly larger than the gas flow of the lube oil system.

(3) Pressure: The pressure of the compression and drying system needs to match the working pressure of the lubricating oil system. If the pressure of the compression drying system is too low, the effect of removing moisture and pollutants cannot be achieved; if the pressure of the compression drying system is too high, the energy consumption and cost of the equipment will be increased.

(4) Dew point: Dew point refers to the temperature at which the moisture in the air begins to condense into liquid water. The dew point should be considered when selecting a compression drying system suitable for the lubricating oil system of the wind turbine gearbox. Generally, the dew point should be lower than the minimum operating temperature of the lubricating oil system. If the dew point is too high, the effect of removing moisture cannot be achieved.

(5) Equipment cost: The prices of compression drying systems of different models and specifications are different, and they need to be selected according to actual needs. At the same time, it is also necessary to consider factors such as equipment maintenance costs and operating costs.

The structure of the compression drying system for wind turbine gearbox lubricating oil:

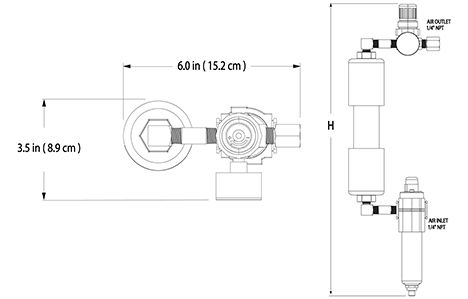

The system is mainly composed of air compressor, filter, membrane dryer and control system. Among them, the compressor is responsible for compressing the air and sending it to the filter and the membrane dryer. The filter is used to remove the particles in the lubricating oil, and the membrane dryer is used to remove the moisture in the lubricating oil. The control system is responsible for monitoring and controlling the operating status of the entire system.

The dehydration device of LK oil tank air drying system controls the increase of moisture from the source, keeps the water content in the medium at the lowest level and can remove the existing moisture in the medium, which can replace the vacuum dehydration device products.

Material: polymer film

Product end cover quality: 6061 aluminum alloy

Filter requirements: 0.01um (if installed on oil air compressor)

Drying dew point of compressed air: 20 degrees to -40 degrees

Pressure drop: 0.1-0.25Bar

Filtration accuracy: 3um, 1um, 0.01um

Seal material: imported seal NBR

Maximum working temperature: 0-60 ℃

Features

Helps minimize equipment wear and improve system reliability

No need to replace expensive desiccant respirators

· Minimize the possibility of entry of particles or water

· Prevent the formation of condensation and rust in the reservoir

Helps reduce the amount of dissolved moisture in the oil

Designed for standard air operation without instrument quality air

The selection of compression drying system suitable for the lubricating oil system of wind turbine gearbox needs to consider the working environment, gas flow, pressure, dew point and other factors. The importance of the correct choice of compression drying system for the lubricating oil system of wind power gearbox is that it can effectively remove the moisture in the lubricating oil, reduce oxidation and pollution, etc., thereby extending the service life of the lubricating oil, reducing the number of equipment maintenance and replacement, and reducing maintenance costs And equipment failure rate. At the same time, the correct installation and regular maintenance of the compression drying system is also an important measure to ensure its normal operation and prolong its life. Therefore, it is very important to choose the right compression drying system for wind turbine gearbox lubricating oil.

Lubricating oil, drying, compression, moisture, removal, gearbox, reduction, air compressor, air compression, wind power, wind power cost reduction, equipment maintenance

Meet at "Road Transport Vehicle Show"

2024-03-11

2024-03-11

Gems president to visit our company exchange

2024-03-11