2024-03-11

Air compressor: how to provide reliable and stable compressed air source for pneumatic soft robot?

With the continuous development of society and science and technology, the application field of robots continues to expand, and the requirements for robots in special fields such as medical care and complex terrain exploration are becoming more and more stringent. Special robots that can adapt to unstructured environments have become a hot research direction in the scientific community.benefit fromContinuous breakthroughs in materials science, chemistry, control and other disciplines,researchers throughto mollusc organisms in nature (suchOctopus, worm, starfish)Observation and modeling,developed asoft robot.

As an emerging branch of robotics,soft robotAdopt hyperelasticity/Soft substance material such as polymer, silicone, rubber, etc. as the body. At the same time, its driving form is not limited to traditional drivers such as motors. New intelligent drivers with various forms and different characteristics, such as pneumatic drive, memory alloy, dielectric drive and chemical drive, also provide the possibility for various special structural designs of soft robots.

The most core and basic key technology of the soft robot is the soft drive. AndPneumatic soft driveIt was first used in the design of soft robots. And because it has the characteristics of light weight, high efficiency, no pollution, strong environmental adaptability, and no need for ferromagnetic or electronic components to drive, no moving parts, good flexibility, and strong radiation, electromagnetic interference, dust and external force It has advantages such as good reliability under harsh conditions such as crushing and heavy hitting,Pneumatic soft robot has been widely concerned and studied by researchers, and occupies an important position in the research of soft robot.

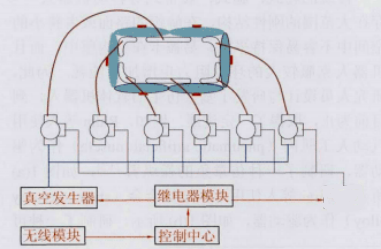

The working principle of the pneumatic soft drive is essentially based on gas as the working medium, and the elastic cavity is under the action of working air pressure (positive pressure or negative pressure) and structural constraints in a certain spatial dimension (such as axial, bending, torsion, etc.) Directional expansion or contraction.Thus, the software robot in the realization of precise axial contractionIt is essential to provide a continuous, stable and reliable compressed air source for the pneumatic drive during the movement of/elongation, bending/swing, torsion/rotation, spiral/winding, etc.

ItalyWERTHER Group, after 40 years of development, has become a world-renowned compressor and vacuum pump manufacturer..By virtue25 years of compressor manufacturing experience, especially in the field of silent compressor has an absolute technical advantage.

Tianjin Liankesi Technology Development Co., Ltd. as an ItalianWERTHER China exclusive agent, to provide high-quality pre-sale, sale, after-sales service.

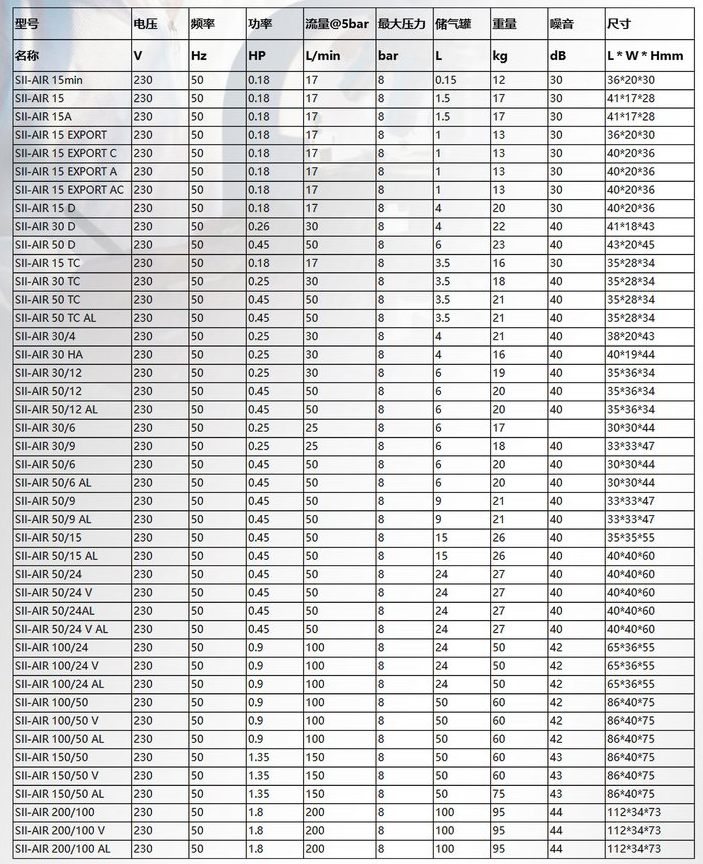

ItalyThe WERTHER ultra-quiet, portable compressor has the characteristics of stable performance, low vibration, simple structure, small size, light weight, and maintenance-free. According to the national standard "GB/T 15487-1995 Volume Compressor Flow Measurement Method", S1 working motor can ensure that the compressor can work continuously under the pressure of user demand, and at the same time, the output of high efficiency and low loss is stable. Reference《GB/T4980-2003Compressor Noise Assessment "standard for noise testing, the compressor in the process of providing a stable air source for pneumatic soft robots to low noise.30dB(A).

Excellent working performance, whispering noise and almost inaudible vibration makeWERTHERCompressors have become the ideal solution for compressed air sources in pneumatic drive systems for soft robots.

Tianjin Liankesi Technology Development Co., Ltd. as an ItalianWERTHER China exclusive agent, to provide high-quality pre-sale, sale, after-sales service.

ItalyThe WERTHER ultra-quiet, portable compressor has the characteristics of stable performance, low vibration, simple structure, small size, light weight, and maintenance-free. According to the national standard "GB/T 15487-1995 Volume Compressor Flow Measurement Method", S1 working motor can ensure that the compressor can work continuously under the pressure of user demand, and at the same time, the output of high efficiency and low loss is stable. Reference《GB/T4980-2003Compressor Noise Assessment "standard for noise testing, the compressor in the process of providing a stable air source for pneumatic soft robots to low noise.30dB(A).

Excellent working performance, whispering noise and almost inaudible vibration makeWERTHERCompressors have become the ideal solution for compressed air sources in pneumatic drive systems for soft robots.

Tianjin Liankesi Technology Development Co., Ltd.It is a domestic integrated supplier dedicated to R & D, design, assembly, and production of compressed air systems, post-processing and supporting equipment, with independent intellectual property rights and a number of technical patents.

Division IYesHigh-tech Enterprises Recognized by Tianjin Municipal GovernmentIt has a professional R & D team, which can provide integrated services of design, R & D, production and sales according to customer requirements. Over the years, adhering to the "quality-oriented, technology first, service leading" business philosophy, and has been determined to continue to innovate, improve the management system, and constantly enhance the competitiveness of products. Welcome friends from all walks of life to contact and cooperate to discuss!

Sales Hotline:15822721002 (Manager Zhang)

18698032466 (Manager Li)

Electronic E-mail:rosezhang@linkstrong-tech.com

Company Website:www.linkstrong-tech.com.cn

Robot, software, compressor, drive, drive, pneumatic, work, provided, werther

Meet at "Road Transport Vehicle Show"

2024-03-11

2024-03-11

Gems president to visit our company exchange

2024-03-11