-

-

Oil-free air compressor

-

Air System Solutions

-

Rail Transit Industry

-

Laboratory Testing

-

New energy electric bus

-

Nitrogen generator

-

Medical industry

-

Dental therapeutic apparatus

-

Portable compressor solution

-

-

Post-processing equipment

-

Hydrogen Energy Solutions

-

System Accessories

-

Electric proportional valve

-

Hydraulic proportional valve

-

Pressure Sensors/Transmitters

-

Mass flow meter/controller

-

Pressure switch

-

Level switch

-

Flow switch

-

Metal powder sintering

-

Other

-

-

2024-03-11

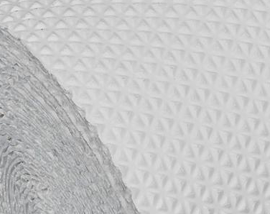

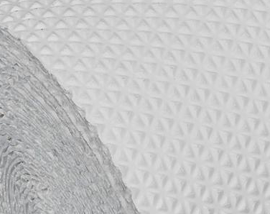

Comparison of drum adsorption media with existing dryer materials

ReelAdsorption media technology is a unique adsorption media. An adsorption sheet is composed of a high content of adsorbent and uses a durable polymer binder, which can produce rapid adsorptionanddesorption kinetics and low energy consumption. WillReelAfter the technology is integrated into the compressed air dryer, it can provide a very durable long-life product.ReelThe durability ensures that even if it is full of condensate or excessive air circulation,Reel(Once restored to normal state) will also fully restore its performance.

traditional clay binding agent

acting as adsorbent material (e. g. adsorption dryer),There areThe following disadvantages:

1. Drying beads will precipitate, causing difficulties in horizontal installation.

2. Vibration will destroy the structure of the drying bead, produce impurities and cause the base layer to collapse, which in turn causes such as: channeling, bypass, bed flow

chemical, orientation, dust generation, misuse (overflow), short service life and degradation due to high water load;,

3. As the bed is saturated, the crushing strength of the beads will be greatly reduced, and the adsorbent beads will become dust, which may be related to condensation. The water binds and spreads downstream, causing malfunction or damage to pneumatic equipment.

Material Characteristics of Membrane Dryer

1、 Membranes have a limited lifetime and are expensive, necessitating a high level of inlet filtration.

2、 Continuous purging can lead to unnecessary compressor use, which greatly shortens the service life of the compressor.

3、 If the membrane is depressurized by the activation of the compressor, the fatigue of the fragile membrane fibers can lead to cracking and loss of air supply.

4、 Membranes are susceptible to chemical attack, suffer catastrophic failure due to shock and vibration, and maintenance costs can be high.

Characteristics of drum suction media:

1, Open structure, fast dynamic reaction

The porous structure makes the adsorption crystals easier to pass, and each adsorption crystal is fully exposed to adsorption on both sides./Desorption process

2, adsorption regeneration speed

Adsorbed water molecules enter the structure more easily

3, high efficiency

Better dynamic performance compared to dry beads

4, high affinity

Relative humidity lessThe absorption amount is 20% wt in the case of 10%

5, high shock resistance

Not affected by direction and vibration

6. High corrosion resistance

Adsorption, structure, vibration, compressor, medium, oil-free air compressor, drum adsorption dryer, compressed air dryer, membrane dryer

Meet at "Road Transport Vehicle Show"

2024-03-11

2024-03-11

Gems president to visit our company exchange

2024-03-11

Business cooperation:022-83718095

Customer service hotline: 022-83713191

Customer Service Email:Sales@linkstrong-tech.com

Address:Hengtong Enterprise Port E32, No.1 Sizhi Road, Xuefu Industrial Park, Xiqing District, Tianjin