2024-03-08

The Importance of Compression Drying System to EH Oil System

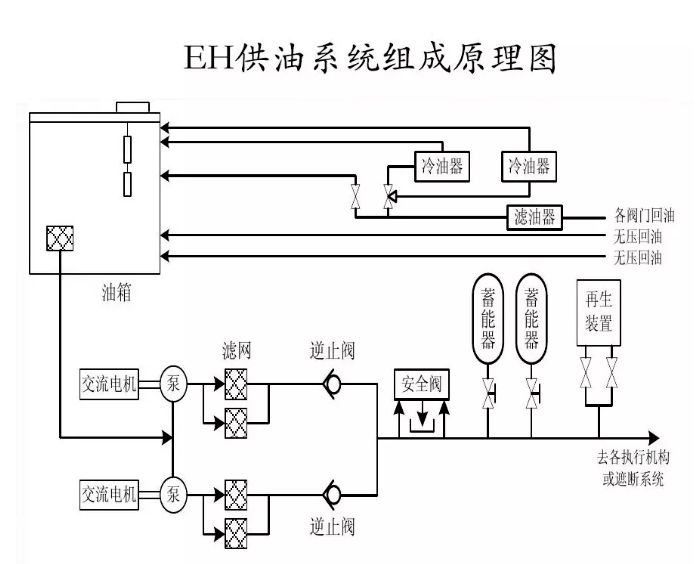

The EH oil system is the turbine speed regulating oil system, also known as the high-pressure fire-resistant oil system, mainly because the turbine speed regulating oil system and the lubricating oil system are independent, using high-temperature resistant oil (EH oil), and using high oil pressure to control the main steam valves and speed regulating valves of the turbine, so it is also called the turbine EH oil system.

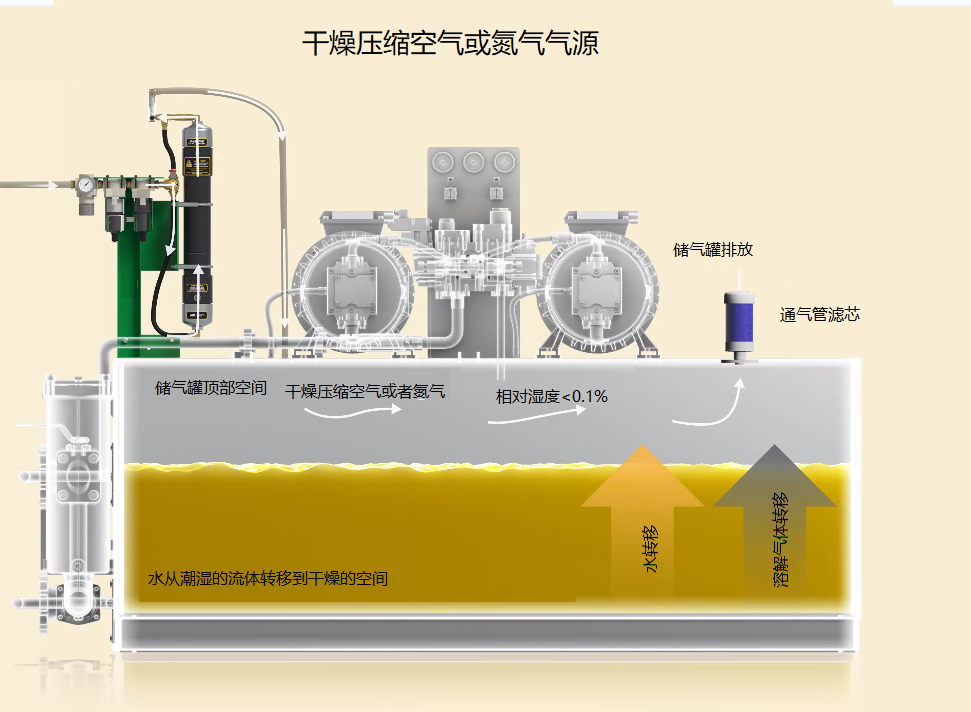

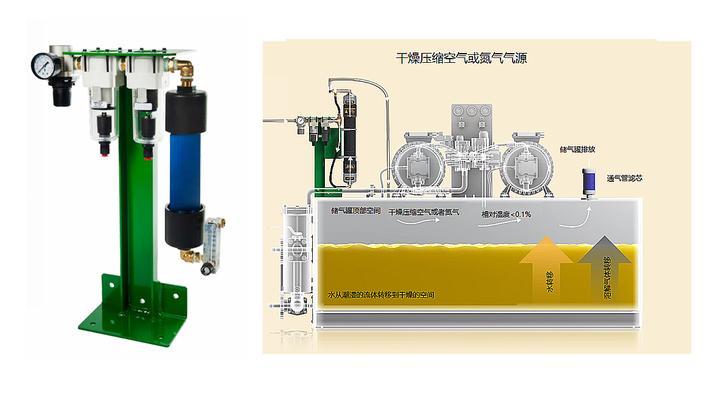

The working principle of the EH fuel tank micro-positive pressure device The EH fuel tank micro-positive pressure device is a device that realizes automatic oil circulation by controlling the gas pressure inside the fuel tank. It is mainly composed of pressure sensors, control valves, fuel tanks and pipelines. When the gas pressure inside the fuel tank is lower than the set value, the control valve is automatically opened to introduce the external gas into the fuel tank to increase the gas pressure, thereby pushing the oil flow. When the gas pressure inside the tank exceeds the set value, the control valve automatically closes to keep the pressure stable. EH oil supply system consists of EH oil tank, EH oil pump, inlet and outlet valves, filter screen, control block, overflow valve, accumulator, EH oil supply and return pipe, oil cooler, a set of self-circulating oil filter system and self-circulating cooling system.

The most harmful and damaging contaminant found in hydraulic and lubrication systems is water. Sources of water pollution may come from mechanical processes or atmospheric intrusion. In a system that is vented to the atmosphere, the moist air above the lubricant transfers water by condensation. While breathing elements provide some relief, they do not prevent water intrusion in the atmosphere.

The Concorde compression drying system provides unlimited water removal and the ability to eliminate atmospheric water intrusion. High-dry compressed air or high-purity nitrogen is introduced into the reservoir headspace above the lubricating oil surface to form a gas shield. When clean, dry compressed air/As the nitrogen sweeps through the reservoir, it acts as an insulator. This eliminates the infiltration of moisture in the atmosphere. Water can exist in three forms: free, dissolved and emulsified. Free water is excess water above the saturation point of the fluid, visible as a separate layer. Dissolved water is below the saturation point of the fluid and is not visible. Emulsified water is the point between free water and dissolved water where the water first appears as a mist. The key point is that just because you can't see water doesn't mean it doesn't exist.

For active hydraulic oil and turbine lube oil maintenance, it is important to manage the drivers of oxidation. The UNCO compression drying system eliminates contact with fluids

Characteristics and benefits of drying systems

through the free flow of high purity nitrogen/Dry compressed air to eliminate the intrusion of atmospheric water, particles and metal ions

Keep the water at a very low level.(Total content <50ppm or EHC fluid <350ppm), reduce the decomposition rate of lubricating oil

PromotionRemoval of H2, CO, C2H4 and other harmful decomposition gases

Extend fluid life

Very low maintenance requirements

Immediate return, high return on investment

Compression drying systemImportance of EH Oil System

(1) Protect the equipment of the speed regulating oil system: The equipment in the speed regulating oil system of the steam turbine, such as valves and oil pumps, plays a key role in the supply and control of the speed regulating oil. The moisture and impurities in the compressed air will cause corrosion and wear on these equipment, reducing its life and performance. The compressed air drying system of the EH fuel tank can effectively remove the moisture and impurities in the compressed air, protect the speed regulating oil system equipment from damage, and extend its service life.

(2) Improve the stability of the speed regulation system: The speed regulation oil system requires stable oil pressure and flow to ensure the stable operation of the steam turbine. The moisture and impurities in the compressed air will increase the foam and pollutants in the oil, which will affect the flow performance and speed control accuracy of the oil. The compressed air drying system of EH fuel tank can effectively remove the moisture and impurities in the compressed air, reduce the foam and pollutants in the oil, and improve the stability and accuracy of the speed control system.

(3) Prevent oil pollution: The oil in the speed control oil system often needs to be transported and controlled by compressed air. If there is moisture and impurities in the compressed air, it will cause oil pollution and affect the lubrication performance and transmission efficiency of the oil. The compressed air drying system of the EH fuel tank can effectively remove the moisture and impurities in the compressed air, maintain the cleanliness of the oil, and reduce the risk of oil pollution.

(4) Improve the reliability of the equipment: The stability and reliability of the speed regulating oil system are very important for the normal operation of the steam turbine. The application of the compressed air drying system of the EH fuel tank can improve the stability and accuracy of the speed control system, reduce the risk of equipment damage, and improve the reliability and operating efficiency of the steam turbine.

To sum up, The compression drying system of EH oil tank plays an important role in the governing oil system of steam turbine. By protecting the speed regulating oil system equipment, improving the stability of the speed regulating system, preventing oil pollution and improving the reliability of the equipment, the EH oil tank compression drying system can improve the operating efficiency and reliability of the turbine. Therefore, in the design and maintenance of steam turbines, the application of the EH fuel tank compressed air drying system should be fully considered to ensure the normal operation and performance optimization of the steam turbine.

System, speed control, eh, oil tank, compressed air, dry, oil, turbine, improve, turbine maintenance

Meet at "Road Transport Vehicle Show"

2024-03-11

2024-03-11

Gems president to visit our company exchange

2024-03-11