2024-03-08

Application of Compressed Gas Source in Automatic Soxhlet Rapid Solvent Extraction System

The characteristics of 1. automatic Soxhlet rapid solvent extraction system are introduced:

The automatic Soxhlet rapid solvent extraction system is a new generation of Soxhlet extraction system with very good performance in existing laboratories on the market. It applies the latest patented Soxhlet extraction technology and integrates a complete solvent treatment device. Fast and efficient, widely used, is widely used in agriculture, food, environment and industry and other different fields, can quickly and safely determine the soluble compounds in food, feed, soil, polymers, textiles, pulp and other products, can be processed at the same time Up to 24 different samples, continuous and reliable to provide the best analysis results.

Its main advantages are:

1. No supervision is required, and the system processing is the most simplified. As long as the extraction cup is put into the extraction cup and the instrument is operated, the control software monitors and records all steps and instrument data throughout the process. It not only makes the extraction process clear at a glance, but also can be traced back at any time.

2. Each extraction part can be carried out independently. In this way, different samples can be extracted with different solutions at the same time, and fully automatic work ensures that the minimum labor force is used and the most stable and reliable results are obtained.

3. The sealed solvent adding system reduces the volatilization of solvent.

4. The automatic control of cooling water and compressed air greatly reduces the operating cost, saves water, protects the environment, and is safe and reliable.

5. All programs automatically switch, independent operation, automatic shutdown function supports overnight operation.

6, cooling water and compressed air pressure monitoring, the system automatically shut down to ensure safety features.

Detection principle of 2. Soxhlet leaching system:

The Soxhlet leaching system is divided into two steps: leaching and extraction. For example, in fat detection, extraction is to raise the material to be measured (powder or paste) to a certain temperature for condensation and reflux, so that the fat in it is dissolved in a solvent (ether or other organic matter). This step is usually carried out for 60-80 minutes in order to dissolve all the fat in the sample. Extraction is a process of separating the solvent from the fat after the fat is separated from the object to be measured. After the solvent is separated and recovered, the substance in the extraction cup is fat, and the fat content divided by the mass of the object to be measured is the fat content of the object to be measured. This is a physical method that uses the principles of chemical similarity and compatibility, as well as the different boiling points of fats and solvents.

The basic components of the Soxhlet leaching system include a set of extractors, a set of control devices and a set of driving devices. The sample to be analyzed is weighed in the leaching paper cylinder and then loaded into the extractor, the solvent is added in the closed system, and the leaching cup is heated by the electronic heating plate. The extraction procedure consists of four steps: hot leaching, leaching, solvent recovery and pre-drying.

Equipment requirements for 3. Soxhlet leaching system:

1. In addition to the main machine, controller or manager, only a few accessories are needed to conveniently complete all the analysis operations in the whole process, mainly including extraction cups, filter cartridges and filter cartridge holders (suitable for filter cartridges of various specifications, which can be used as long as they can be installed). Cup clamps and sealing rings are also randomly equipped. In addition, an air supply system (noise-free air compressor) is equipped for pneumatic control, which is simple and has few failures.

2. Technical parameters:

Voltage: 230VAC-50/60Hz

Power: 400W-1200W (different models)

Weight: 28kg-42kg (different models)

Temperature: Maximum 300°C

Water consumption: 0.5-3.5L/min

Water pressure: minimum 0.3bar

RS 485 interface: 2

3, to comply with the official approval of the test method

AOAC 991.36 (Meat)

AOAC 2003.5,2003.6 (feed)

SCAN-CM49:93 (pulp)

EPA No.3541 (Soil)

4, comply with international and domestic standards of extraction standards, can be used in almost all areas of analysis, to meet the requirements of analysis quality.

The explosion-proof electrical system must meet the strict requirements of DIN/VDE 0170 and 0171.

Application of compressed gas source for 4. automatic Soxhlet rapid solvent extraction system:

Automatic Soxhlet rapid solvent extraction system is a kind of equipment used in flammable and explosive dangerous environment, its structural design, especially its electrical control part, in full accordance with international electrical standards, strictly follow the explosion-proof specifications, and creative use of pneumatic drive technology, greatly optimize the structure of the system, practical and trouble-free. Just because it complies with the most stringent safety requirements and belongs to the high-level operation safety of the laboratory, it is necessary to ensure extremely high safety when using the extraction solvent, convenient operation, economy and speed. In order to ensure the normal use and prolonged service life of the air compressor in this automation equipment, it does not require daily maintenance and has low noise, and the most suitable is the imported original Italian WERTHER silent oil-free compressor. Werther oil-free air compressor systems produce air that fully meets the air quality requirements of ISO8573-1 standards, making it particularly suitable for sensitive laboratory applications. Soxtherm extraction reduces the consumption of water and solvent and significantly shortens the extraction time. The compact design requires less laboratory space. A fully automated system recovers and stores used solvents and maintains cooling water temperatures. The unit accepts multiple thimbles and can be used with all common solvents.

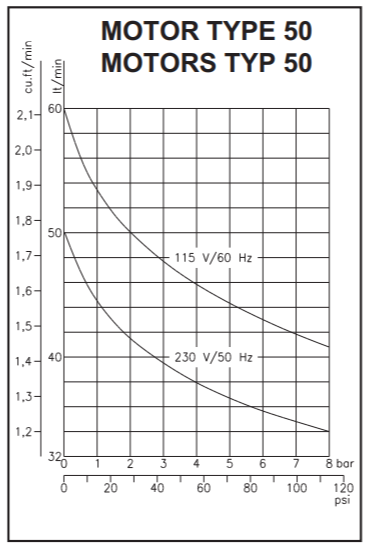

At present, the most well-known Soxtherm Soxson-automatic Soxhlet rapid solvent extraction system is the product of Gerhardt since1846, a professional German laboratory instrument company-Gerhardt Analytical Instruments Co., Ltd., which fully complies with the German Electrical Appliance Standard (DIN) design and provides top safety specifications. The system has the advantages of water and compressed air control to realize unattended operation, save water and make the system more environmentally friendly. Among them, the recommended air monitoring for SOXTHERM units WERTHER the original imported silent oil-free air compressor. The air compressor has a voltage of 230v, 50hz, an inlet pressure of 65psi, and a maximum working pressure of 8bar, in which the air must be dried and filtered (5µ).

Among them, the high-quality Werther ultra-quiet compressor is ideal for automatic Soxhlet rapid solvent extraction systems due to its small size, high efficiency and long-lasting performance: no maintenance of the compressor is required during the entire service life of the equipment.

Advantage

-Silent compressor with oil

-100 duty cycle

-Performance: 340 W

-High quality pump head

-Maximum pressure: 8 bar (116 psi)

-Air flow: 50L/min

-Gas tank: 3.5 L stainless steel

-Noise level: 40dBA

-Weight: 22kg

-Dimensions: 360 x 300 x 350cm

-Built-in water separator

After 40 years of development, the Italian WERTHER Group has become a world-renowned manufacturer of compressors and vacuum pumps. With 25 years of compressor manufacturing experience, it has absolute technical advantages especially in the field of silent oil-free compressors (noise below 45 decibels).

As the exclusive agent of Italy WERTHER China, Tianjin Lianke Sichuang Technology Development Co., Ltd. provides high-quality pre-sale, in-sale and after-sale life cycle services.

Werther air compressors are widely used in laboratories: nuclear magnetic resonance, tensile testing machine, blood analysis equipment, humidity meter, laser particle sizer, atomic absorption meter, Peak,Parker,Claind, and other brands of nitrogen generators, Agilent Agilent, Thermo Fisher, AB SCIEX,Waters and other brands of gas chromatographs and gas mass spectrometers, EISS,FEI, Hitachi, Jeol and other brands of electron microscopy. Medical industry: dental supporting air compressor, ICU, operating room centralized gas supply, pneumatic ballistic gravel. Werther company has been focusing on providing oil-free compressors for various fields such as medicine, environment, food, etc. Its authorized agent in China, Tianjin Liankeschuang Technology Development Co., Ltd. Due to many years of experience, we have the ability to provide you from project conception to installation. Provide advice and ensure that you are satisfied after purchase. We are happy to advise you, please contact us.

Tianjin Lianke Sichuang Technology Development Co., Ltd. is a domestic integrated supplier dedicated to R & D, design, assembly, and production of compressed air systems and post-processing and supporting equipment. It has independent intellectual property rights and a number of technical patents.

Our company is a high-tech enterprise recognized by the Tianjin Municipal Government, with a professional R & D team, which can provide integrated services of design, R & D, production and sales according to customer requirements. Over the years, adhering to the "quality-oriented, technology-oriented, service-leading" business philosophy, and has been determined to continue to innovate, improve the management system, and constantly enhance the competitiveness of products. Welcome friends from all walks of life to contact and cooperate to discuss!

Sales Hotline:15822721002(Manager Zhang)

Electronic E-mail:rosezhang@linkstrong-tech.com

Company Website:www.linkstrong-tech.com.cn

Solvent, system, fully automatic, fast, fat, compressor, use, werther, operation

Previous Page

Meet at "Road Transport Vehicle Show"

2024-03-11

2024-03-11

Gems president to visit our company exchange

2024-03-11