2024-03-11

Compressed gas source solution for pulsating vacuum sterilizer

1.Application range of pulsating vacuum sterilizer:

Pulsating vacuum sterilizerIs the current advanced technology, reliable effect, high efficiency of sterilization equipment,Mainly used to steam cavity items and appliances, etc.Sterilization. In the pharmaceutical industry, it can sterilize the bottle stopper, operating tools, a large number of work clothes and other cloth items or drugs that do not need to be cooled and explosion-proof. It can also be used as sterilization equipment for units producing sanitary materials, dressings, instruments and other products in the pharmaceutical industry. It can be used for sterilization, fumigation and drying of medicinal materials. Can also be used for food sterilization.

In the medical industry, with the increasing attention of major hospitals to nosocomial infection, the traditional exhaust sterilizer has been gradually eliminated and replaced by pulse sterilizer. Among all kinds of disinfection and sterilization equipment in the hospital, pulsating vacuum sterilizer plays an irreplaceable role in the sterilization of daily dressings, instruments and other items. As the most important equipment in the hospital supply room, pulsating vacuum sterilizer undertakes the sterilization task of most daily items and can kill all living microorganisms on medical equipment, including bacteria, spores, viruses and fungi, so as to ensure the safety and repeated use of these equipment.

2.Working principle of pulsating vacuum sterilizer:

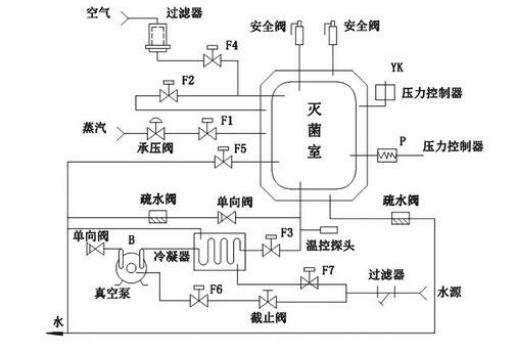

The principle isSaturated steam as a sterilization medium, through the mechanical forced exclusion of air in the sterilization chamber, inRepeated vacuuming and repeated injection of steamUnder the action of the sterilization chamber, the formation of negative pressure, whenAirPumpingamount99%After the aboveThen fill the saturated steam to reach the set temperature and pressure, and the steam can quickly penetrate into the inside of the article for sterilization. Pulsating vacuum due to multiple vacuuming, more thoroughly exclude the sterilization chamber and waiting.Sterilized ArticlesThe cold air inside,Allow the pressure steam to quickly penetrate into the center of the item to be sterilized,Completely eliminate the temperature "dead angle" and "small load effect", air exclusion more thoroughly,Thermal penetration is more rapid, Sterilization at higher temperatures,Shorter sterilization time required,The effect is more stable and reliable.

3. compressed air sourceImportantRole:

Pulsating vacuum sterilizerIt is a multi-medium equipment integrating high-pressure steam, water, electricity and compressed air,Among them, water source, power supply and pressureThe shrinking air source is the main driving force for the operation of the various components of the pulsating vacuum sterilizer. Therefore, whether the air compressor can be efficient, safe and accurate operation plays an important role in conveying compressed gas.

Compressed air is mainly usedPulsating vacuum sterilizerThe main function of the sealing of the cabinet door and the switch control of all pneumatic valves of the equipment is to compress air all the way to the pilot solenoid valve to control the opening and closing of each pneumatic valve, and the other way enters the front and rear sealing grooves through the two-position five-way reversing valve to control the sealing rubber strip Air intake and evacuation, so as to realize the sealing of the door.Sealed doorGeneralwith electrical and mechanical pressure safety interlocks,When running the sterilization program, the inner chamber is completely sealed and isolated from the outside world to ensure sufficient sterilization.

Good choice of 4. air compressor:

Pulsating vacuum sterilizer is a mechatronics equipment with high degree of automation. It has the characteristics of high sterilization quality, many parameters involved and high frequency use but easy to fail. In particular, the required air compressor needs to repeatedly vacuum and inject steam and work alternately for many times. Therefore, to ensure the stability and long-term transportation of compressed air, it also needs convenient daily operation, safety and durability, low noise and low maintenance difficulty. The compressed air used in the pulsating vacuum sterilizer must meet the following requirements,Air pressure range:0.4-0.7Mpa, Oil-free and quiet operation, antibacterial coating inside the gas storage tank, the maximum particle size is5μm.Our high qualityPC90Series without oilThe compressor, due to its small size, isPulsating vacuum sterilizerThe ideal choice. They are characterized by efficient and durable performance:SuchInSterilizer equipmentDuring the entire service life of the compressor, no maintenance is required.

| PC90Technical parameters |

|

| Output flow |

92 L. Min |

| Maximum working pressure |

8 bar |

| Maximum current |

115V 4.8 Amps |

| Noise |

59 db/A |

| Air cylinder size |

3.5L |

| Dimensions (ins.) |

11x13x14 |

| Weight |

41 lbs |

Italy WERTHER GroupAfter 40 years of development, it has become a world-renowned compressor and vacuum pump manufacturer. By virtue25 years of compressor manufacturing experience, especially in silentOil-freeCompressor (noise less 45 decibels) field has an absolute technical advantage.

Tianjin Liankesi Technology Development Co., Ltd.as Italy WERTHER China exclusive agent, providing high quality pre-sale, sale, after-saleFull life cycle services.

Werther air compressors are widely used in laboratories: nuclear magnetic resonance, tensile testing machine, blood analysis equipment, humidity meter, laser particle sizer, atomic absorption meter, Peak,Parker,Claind, and other brands of nitrogen generators, Agilent Agilent, Thermo Fisher, AB SCIEX,Waters and other brands of gas chromatographs and gas mass spectrometers, EISS,FEI, Hitachi, Jeol and other brands of electron microscopy. Medical industry: dental supporting air compressor, ICU, operating room centralized gas supply, pneumatic ballistic gravel. Werther CompanyHas been focused on providing oil-free compressors for hospitals and medical practices, its authorized agent in China, Tianjin Lianke Sichuang Technology Development Co., Ltd.Due to years of experience, we haveAbilityAdvise you from the idea of the project to the installation and make sure you are satisfied after the purchase. We are happy to advise you, please contact us.

Tianjin Liankesi Technology Development Co., Ltd.It is a domestic integrated supplier dedicated to R & D, design, assembly, and production of compressed air systems, post-processing and supporting equipment, with independent intellectual property rights and a number of technical patents.

Division IYesHigh-tech Enterprises Recognized by Tianjin Municipal GovernmentIt has a professional R & D team, which can provide integrated services of design, R & D, production and sales according to customer requirements. Over the years, adhering to the "quality-oriented, technology first, service leading" business philosophy, and has been determined to continue to innovate, improve the management system, and constantly enhance the competitiveness of products. Welcome friends from all walks of life to contact and cooperate to discuss!

Sales Hotline:15822721002 (Manager Zhang)

Electronic E-mail:rosezhang@linkstrong-tech.com

lpyang@linkstrong-tech.com

Company Website:www.linkstrong-tech.com.cn

Pulsation, sterilization, vacuum, sterilizer, equipment, compressed air, steam, article, compressor

Meet at "Road Transport Vehicle Show"

2024-03-11

2024-03-11

Gems president to visit our company exchange

2024-03-11