2024-03-11

Application of Membrane Dryer in Laser Cutting Machine

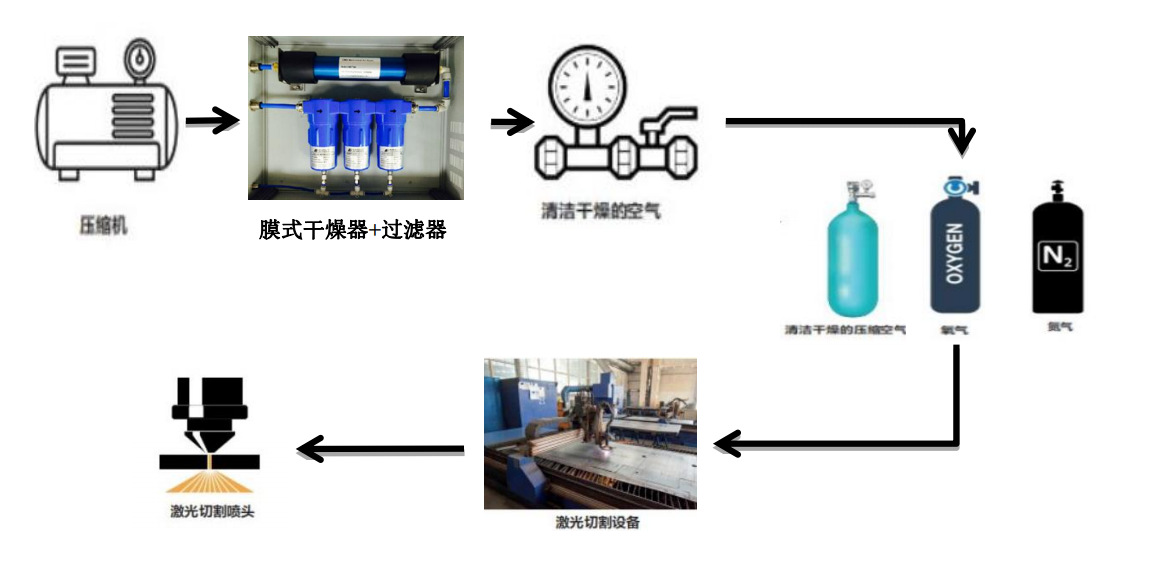

Laser cutting machine is composed of laser, cutting head, servo motor, automatic tracking system, compressed air system, chiller and other equipment.

When it comes to compressed air system, we all know that the laser cutting machine has relatively high requirements for compressed air sources. It requires that the air source cannot contain water and oil, and dry gas. Generally, users will be equipped with four-stage filtration or even five-stage filtration. The purpose is to better protect the service life of the laser cutting machine. If the air source entering the cutting head is not dry, it also contains water and oil, then it will cause fogging of the protective lens in a short time, thus affecting the cutting quality. If the protective lens is not replaced in time at this time, the internal temperature of the cutting head may rise under the irradiation of the high-power beam, resulting in damage to the internal lens group.

The importance of compressed air drying: laser loss will greatly reduce the working efficiency of laser cutting machine. To keep the optical path clean is to use compressed air. If the dryness of compressed air is not enough, the laser beam will be lost due to condensation on the mirror surface. In order to prevent the dryness of compressed air from being insufficient, we can use membrane dryer to dry and purify compressed air, thus we not only increase the efficiency of the whole system, it also improves the reliability of the system and reduces maintenance (saving maintenance costs).

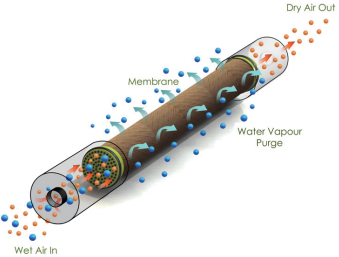

Tianjin Liankesi Technology Development Co., Ltd.Membrane dryer,As a new drying technology,With high-performance hollow fiber membranes, the pressure dew point can be constantly reduced. 5-10 years long life dry film wire, no need to regularly replace the dry material, reduce maintenance costs while ensuring that the pressure dew point is always lower than -30 ℃. Working process without power supply,

Technical principle and advantages of membrane dryer

● Proven air technology with consistent and predictable performance;

Lightweight and compact, easy to install into the existing compressed air circuit;

● Low purge air consumption;

● Mute operation, no moving parts;

● No power supply required;

● Operation without duty;

● No need to collect condensate;

● No consumables (refrigerant or desiccant) required.

As long as there is a gas pressure gradient (concentration difference),

Gas molecules will then penetrate through the solid material to reach equilibrium.

Tianjin Lianke Sichuang Technology Development Co., Ltd. is a domestic integrated supplier dedicated to R & D, design, assembly, and production of compressed air systems and post-processing and supporting equipment. It has independent intellectual property rights and a number of technical patents.

Our company is a high-tech enterprise recognized by the Tianjin Municipal Government, with a professional R & D team, which can provide integrated services of design, R & D, production and sales according to customer requirements. Over the years, adhering to the "quality-oriented, technology first, service leading" business philosophy, and has been determined to continue to innovate, improve the management system, and constantly enhance the competitiveness of products. Welcome friends from all walks of life to contact and cooperate to discuss!

Sales Hotline: 15822721002 (Manager Zhang)

17547092636 (Yang Jingli)

E-mail: rosezhang@linkstrong-tech.com

lpyang@linkstrong-tech.com

Company website: www.linkstrong-tech.com.cn

Cutting, compressed air, drying, system, technology, laser, cutting machine

Meet at "Road Transport Vehicle Show"

2024-03-11

2024-03-11

Gems president to visit our company exchange

2024-03-11