-

-

Oil-free air compressor

-

Air System Solutions

-

Rail Transit Industry

-

Laboratory Testing

-

New energy electric bus

-

Nitrogen generator

-

Medical industry

-

Dental therapeutic apparatus

-

Portable compressor solution

-

-

Post-processing equipment

-

Hydrogen Energy Solutions

-

System Accessories

-

Electric proportional valve

-

Hydraulic proportional valve

-

Pressure Sensors/Transmitters

-

Mass flow meter/controller

-

Pressure switch

-

Level switch

-

Flow switch

-

Metal powder sintering

-

Other

-

-

2024-03-11

Application of LKD system compressed air dryer in manufacturing process

Compressed air is used for more than 70% of all manufacturing activities, from high-demand applications that may affect product quality to general "shop" use. When compressed air is used in the production of medicines, food, beverages, medical equipment and other products, it seems that there is confusion about which tests are required. In many applications, compressed air is used from start to finish

What are the pollutants in compressed air?

The Compressed Air and Gas Institute (CAGI) lists 10 pollutants that usually need to be removed or reduced from the low-pressure compressed air used for manufacturing (rather than breathing air). These pollutants fall into four broad categories:

1. Particles (from pipe scale, wear particles and atmospheric dirt)

2. Water (liquid, vapor and aerosol)

3. Oils (liquids, vapors and aerosols)

4. Microorganisms

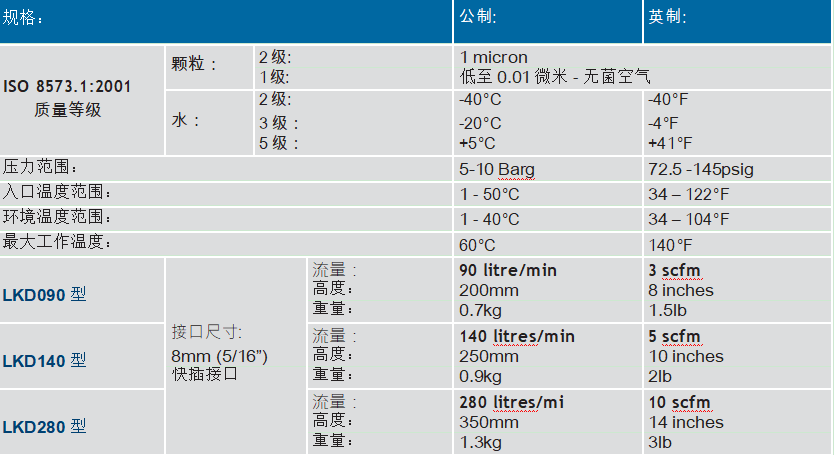

LKD dryer is a new type of compressed air purifier, suitable for installation in the air compressor with a small oil-free storage tank to obtain clean, dry, sterile 2 compressed air, its performance and reliability are far better than other drying technology.

The compact LKD dryer processes compressed air in 5 stages, all integrated inside the dryer. There is no need to install a separate controller, nor to install an external filter and drain, which greatly reduces the installation and use cost of the LKD dryer and makes it more advantageous. LKD dryers are also fully self-healing under abnormal conditions, such as flow overload and accidental inflow of condensate.

LKDThe dryer is one of the most powerful technological innovations in the field of compressed air drying!

Manufacture, compressed air, dryer, lkd, use, pollutant, installation, and gas, sol, vapor

Previous Page

Meet at "Road Transport Vehicle Show"

2024-03-11

2024-03-11

Gems president to visit our company exchange

2024-03-11

Business cooperation:022-83718095

Customer service hotline: 022-83713191

Customer Service Email:Sales@linkstrong-tech.com

Address:Hengtong Enterprise Port E32, No.1 Sizhi Road, Xuefu Industrial Park, Xiqing District, Tianjin